Welcome to Cambridge

ATOMWORKS

Cambridge Atomworks

Cambridge Atomworks is a startup in the Cambridge innovation ecosystem specialising in nuclear engineering and reactor design services. We served as the design authority for the ODIN microreactor in collaboration with NANO Nuclear Energy Inc (NASDAQ: NNE) until the end of September 2025. Our goal now is the development of compact, efficient, and reliable nuclear energy solutions for emerging energy markets designed and built in the UK. We aim to use our close ties to the University of Cambridge to deliver advanced nuclear technologies that will power the energy transition.

Emerging Energy Markets

The provision of economic and reliable power is essential for the successful completion of many endeavours. When the power requirement exists a long way from an electricity grid, diseconomies of scale apply, and the provision of local reliable power becomes expensive and logistically difficult.

Cambridge Atomworks aims to utilise the very high energy density of fission nuclear power to provide reliable power with substantially reduced logistics over long (decadal) time scales to satisfy local power requirements in off-grid situations such as mining, developing countries and remote and island communities.

Mission

To deploy a demonstration nuclear micro-reactor system by the end of the decade. Subsequently, deliver power in an off-grid situation by the early-to-mid 2030s. This reactor will be delivered to site using standard transportation infrastructure and the minimum of on-site works. A very high percentage of off-site advanced manufacturing techniques will recover some of the inherent diseconomies of scale of small nuclear reactors.

Key features of the Odin Reactor

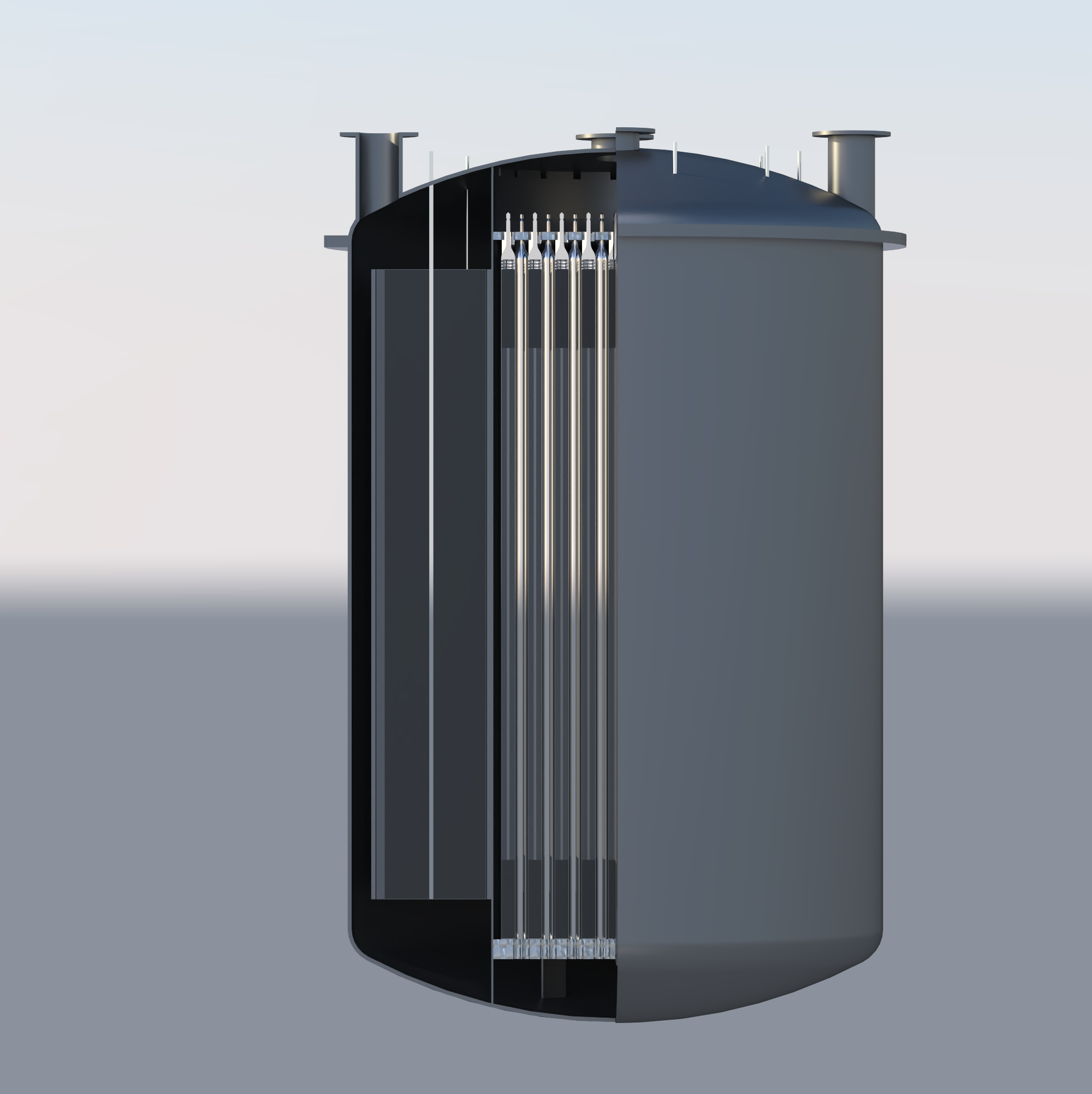

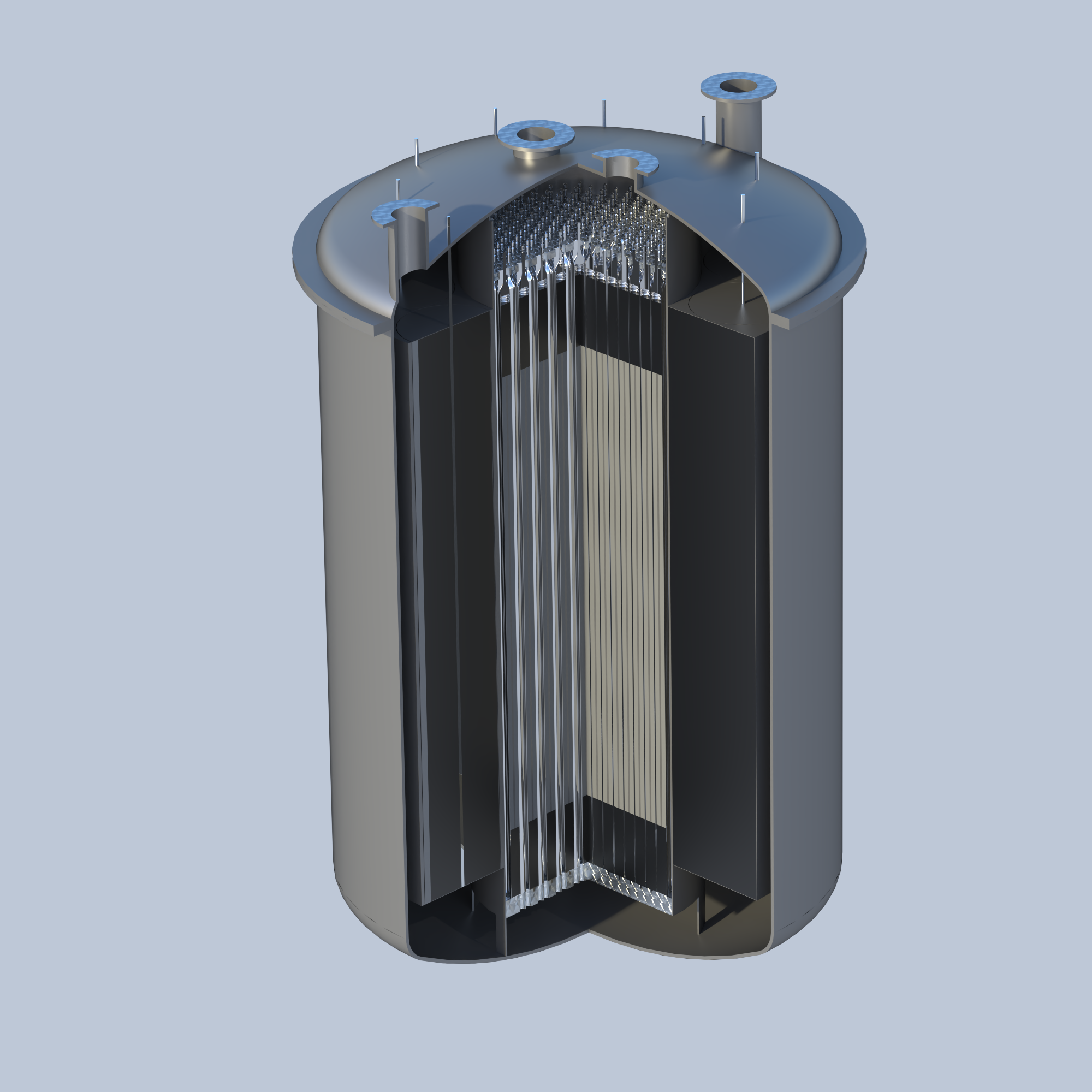

Low pressure coolant - Our salt coolant provides a high temperature liquid without the need for pressurisation. The high fidelity required in the safety qualification of pressure vessels in more conventional water-based reactor concepts is a large safety and cost concern. Low pressure operation with salt has many advantages. The radiation stability of our novel coolant salt will be determined through multiple experimental campaigns using accelerator, gamma and reactor sources at Idaho National Laboratory, Massachusetts Institute of Technology, Department of Nuclear Science & Engineering MITR. These campaigns are under way.

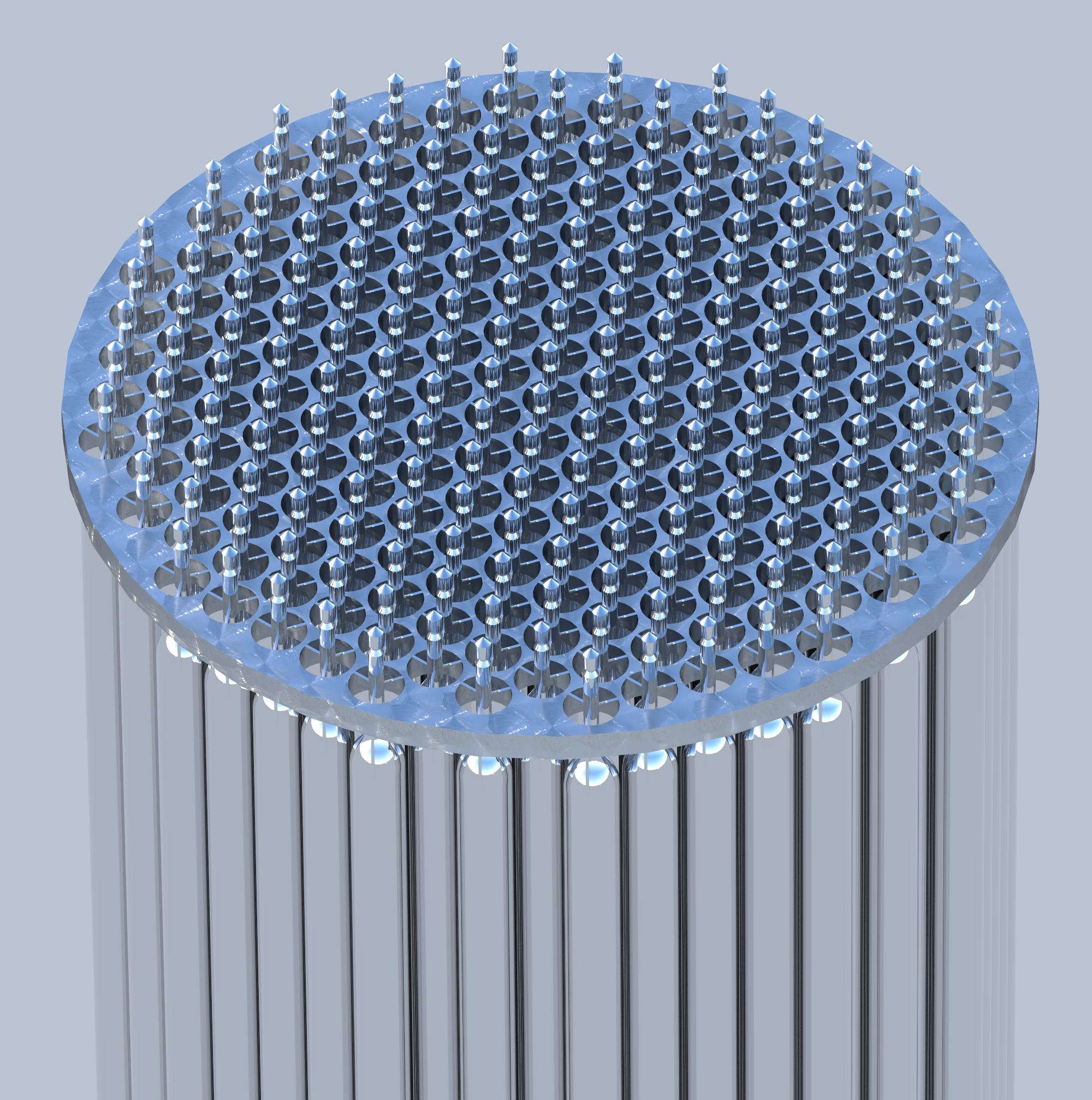

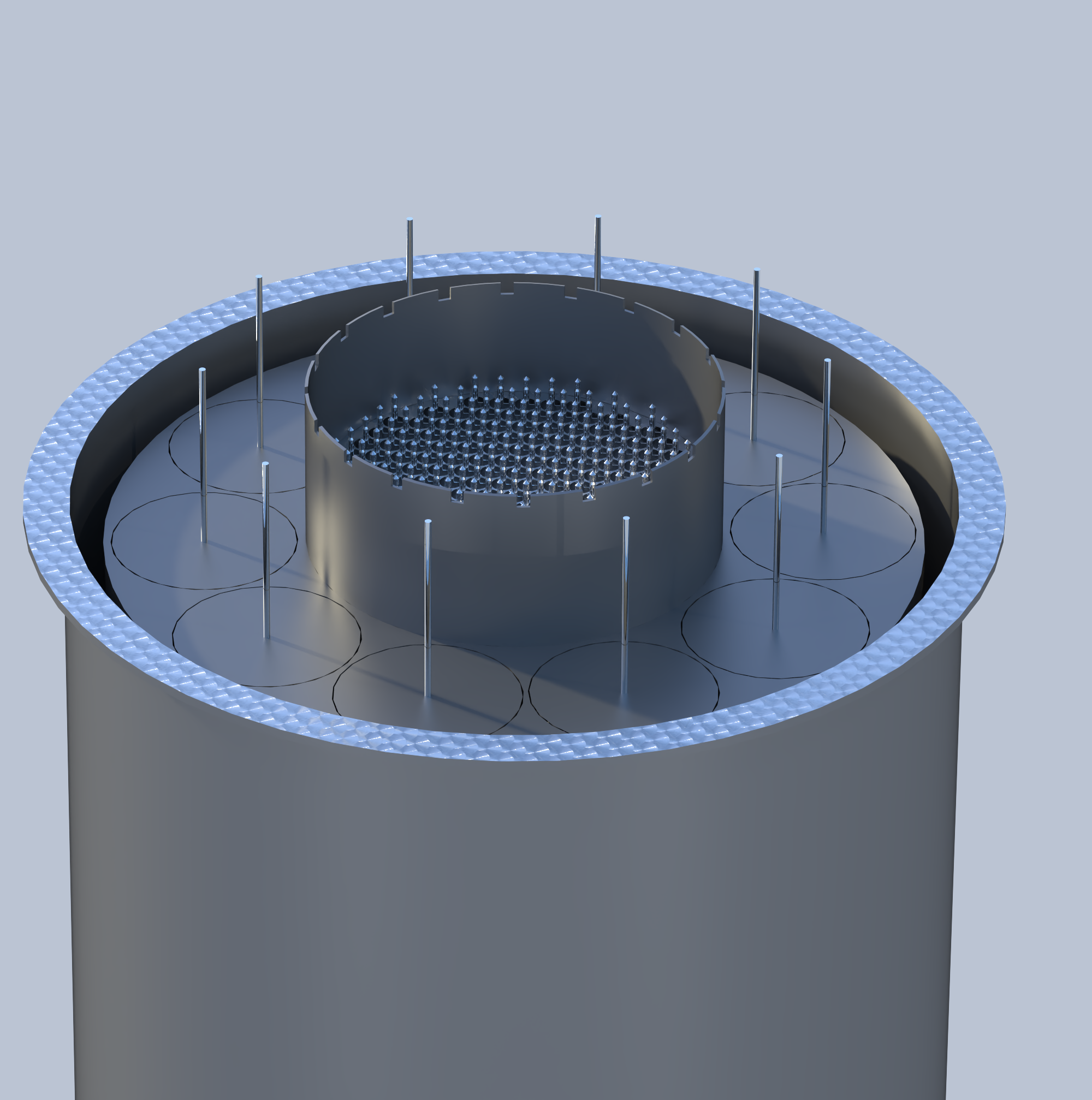

Fuel - A transportable nuclear reactor should be compact. Our fuel choice is a well-established fuel type where moderator and fuel are co-located providing efficient use of space in the reactor core. This fuel is commonly regarded as ‘safe by physics’ having arisen from the Atoms for Peace initiative in the 1950s. It was developed by General Atomics and distributed around the world by the US government to establish research reactors in more than 30 countries.

Safety - The micro-reactor is designed with air as the ultimate heat sink and to be walk-away safe in any deployment scenario i.e., it does not need to be close to a water source. The reactor can be cooled via natural circulation both by the molten salt and the reactor auxiliary air cooling system (RVACS).

Odin Design History - Cambridge Atomworks was set up in January 2023 as a consulting partnership to develop the design of a Transportable Nuclear Micro-Reactor for Nanonuclear Energy Inc. (NNE). It is currently designing the low pressure coolant reactor, ODIN. Cambridge Atomworks took the design through to a pre-conceptual review by the US Department of Energy (NE) at Idaho National Laboratory (INL) in August 2023. The design has been further developed and is expected to achieve the Conceptual Stage in Q2 2026 (NNE started the regulatory engagement process with the US NRC for the ODIN design in October 2024). Following the recent pivot of NNE towards fixed reactors for the datacenter market, Cambridge Atomworks has bought back the intellectual property generated for NNE to create a UK reactor delivery company and deliver a demonstrator micro-reactor in the United Kingdom by the end of the decade and subsequently an off-grid system with an off-grid anchor partner by the mid-2030s.